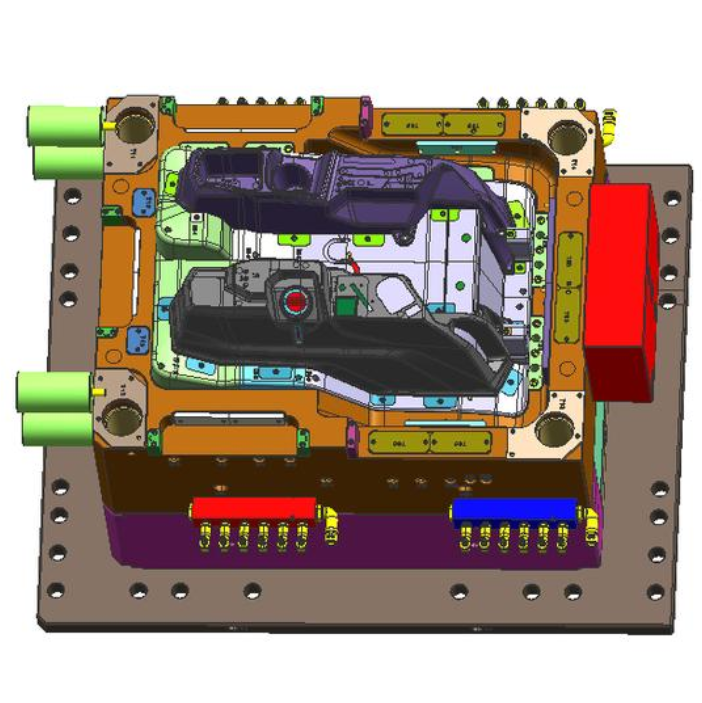

Home > Company News > The use and maintenance method of plastic mold

Company News

The main points are as follows:

(1) Before production, check whether there are impurities in each part of the die. Dirt: the paint, impurities and dirt in the mold shall be scrubbed and removed with cotton gauze, and the residues with strong adhesion shall be cleaned with copper tools.

(2) The clamping force shall be reasonably selected, and the flash shall not occur during product forming. Excessive clamping force not only increases the power consumption, but also makes the die and transmission parts wear faster.

(3) The sliding parts of the die, such as guide post, push rod, reset rod and pull rod, can be oiled twice a day in summer and only once in winter.

(4) When the full-time mold preservation worker is on duty, he shall conduct patrol inspection and observation on the molds in production, and deal with the problems found in time. When the maintenance worker takes over the shift, he should go to work 5 ~ 10 minutes in advance to check the mold production status - especially for those molds that often have secondary scrap, and molds with more and more prominent problems should be paid more attention.

(5) In case of power failure or shutdown for some reason during production, if the machine is shut down continuously for more than 6 hours and the air is wet in the plum rain season in the south, it is necessary to spray antirust oil on the forming surface, parting surface and sliding surface. In case of continuous shutdown for more than 24 hours in non rainy season, anti rust lubricant shall be sprayed on the mold forming surface, parting surface and sliding mating surface. The molds that are not used temporarily and need to be stored in the warehouse shall be thoroughly cleaned before warehousing, and then sprayed with antirust lubricant. After closing the molds, they shall be stored in the warehouse. No heavy objects are allowed on the mold.

(6) It is not allowed to hit any part in the mold with a hammer to prevent knock marks or deformation.

(7) If the equipment is not used temporarily, the mould on the injection shall be coated with anti rust oil. It is not allowed to stay in the mold closing state with pressure for a long time between the moving and fixed molds to prevent compression deformation.

goko mold technology.,ltd from Guangdong -HK-Macao Bay Area of China .We make moulds ,Precision parts machining, plastic parts injection moulding , and provide moulds design and products design. I believe our price will be cheaper at least 15% than your current supplier for the same quality products. We have developed a lot of mobile phone accessories products, we are a manufacturer with price advantage and quality assurance, to provide more help to your business.http://www.gokotechnology.com/

-

silica sol casting butterfly valve precision casting parts

-

CNC machining parts from rough casting valves

-

cast steel soft-sealing sluice valves manufacturing

-

steel CF8M sluice valve manufacturer

-

steel CF8M hydraulic brake valve body

-

stainless steel CF8M brake valve

-

HL Parts | Customized Anodizing Aluminum Parts Mechanical Metal CNC Processing Services CNC Turning And Milling Part Service

-

HL Parts | Factory Custom Motor Cover CNC Machining Anodic Oxidation Parts

-

HL Parts | Custom CNC Machining Service,CNC Machining Parts, CNC Milling Machined Anodized Aluminum Parts Rapid Prototype

-

HL Parts | Black Bakelite Corrugated Hand Wheel Threaded Keyway Valve Switch Knob Female Star Knobs

-

HL Parts | Custom high precision alloy aluminum stainless steel hot forging die casting machining service grey iron sand casting

-

HL Parts | Custom metal Custom Factory Metal Die Cast Metalworking Cast Iron Precision Casting Parts

-

HL Parts | Custom Made High Precision Automatic Micro CNC Machininig Service Aluminum Stainless Steel Brass Milling Turning Parts

-

HL Parts | Mdf Acrylic Hookah Machininig Machine Service Wood Processing Shop Foam Service Services Aluminium Cnc Cnc Machining Part

-

HL Parts | Custom Brass CNC Accessories Metal Spare Precision Turning Mechanical CNC Machining Products Copper Services Parts Supplier

-

HL Parts | Custom Milling Machining Parts Precision Aluminum Milling Part For Bicycle Accessories

-

HL Parts | High Speed Door Zipper Pvc Accessories Or Zipper High Speed Door Accessories High Speed Roll-Up Door Motor/Operator

-

HL Parts | BAP300R End Mill Tool Holder CNC Metal APMT1135 Carbide Insert Arbor Right Angle End Milling Cutter Holder

-

HL Parts | Manufacturer supply high quality Aluminum Handle Brass Valve Brass Low Price Steel Ball Brass Ball Valve

-

HL Parts |EDM Service Huizhou High Precision Aluminum Manufacturing Casting Industry Machined Parts Chemical Machinery Parts Finish

-

HL Parts | CNC RF Connector Accessories TNC Coax Cap male female TNC Dust Cap Protective Cover with Chain

-

HL Parts | Oem Custom Aluminum Stainless Steel Brass Titanium Plastic Cnc Precision Machining Milling Turning Lathe Part Machining Service

-

HL Parts | Custom High Precision Cnc Metal Machining 5 Axis Stainless Steel Brass Aluminum Titanium Cnc Milling Turning Parts

-

HL Parts | Cnc Turning Milling Metal Machining Precision Parts Aluminium Brass Stainless Steel Custom CNC Process Turning Parts